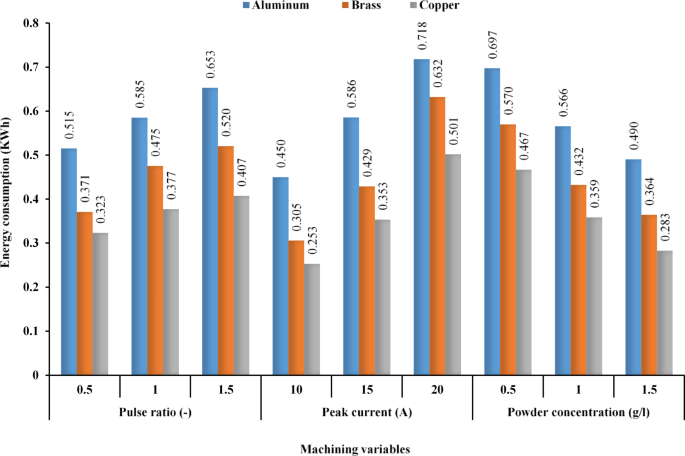

In EDM, EC is mainly driven by the EDM variables; therefore, it is necessary to optimize the EDM variables to limit and utilize energy efficiently. Mean effects analysis shows that the low PR exhibits a lower time span per pulse for the energy supply; thus, EC is lower at 0.5 but increases successively when the PR is raised to 1.5, as shown in Fig. 3. Similar behavior has been observed for all electrodes. IP has been observed to be more sensitive to EC as its increase from 10 to 20 A EC rose from 0.515 to 0.653 kWh for the aluminum electrode. Brass and copper electrodes also exhibit nearly the same trends. A higher IP aims to produce intense sparking to remove workpiece material; thus, more energy is consumed. A distinct behavior has been observed in the case of PC, as the increase in PC from 0.5 to 1.5 g/L decreases EC for all electrode materials. A rise in the quantity of graphene nanoparticles significantly increases the conductivity of the dielectric fluid. This leads to an efficient supply of energy to the machining zone for the workpiece material removal, ultimately reducing the need for a higher amount of discharge energy; hence, EC decreases with higher PC.

Mean effects analysis of EDM variables for EC.

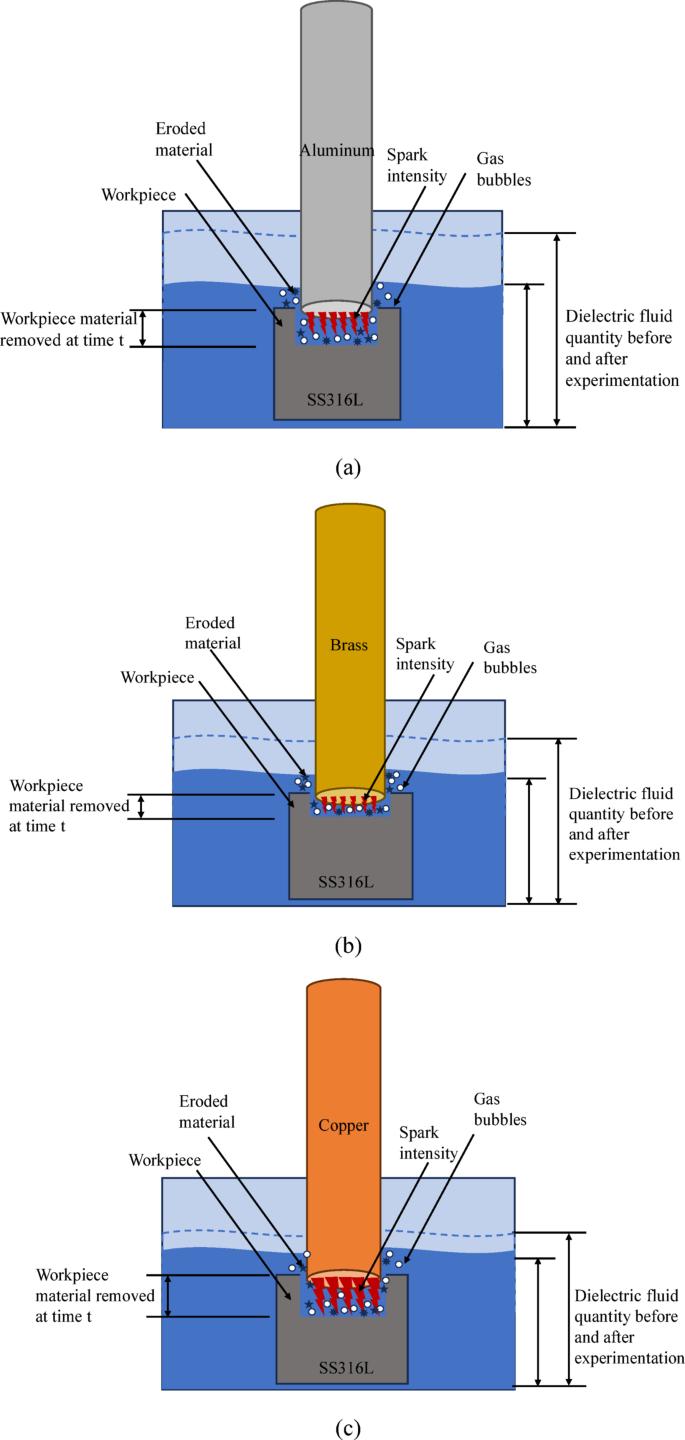

Analysis of electrode materials revealed that aluminum electrode consumed a relatively higher amount of energy, followed by brass, while copper yielded the lowest EC (Fig. 3). EC mainly relies on the electrical and thermal conductivities of the electrodes. In comparison with other electrode materials, brass has the lowest electrical and thermal conductivity. Low electrical conductivity means more energy is dissipated as heat due to resistance, and less spark energy is supplied to the machining zone for material removal. Moreover, brass also has low thermal conductivity and tends to retain heat, resulting in localized overheating (and an increase in electrical resistance); therefore, a higher amount of energy is consumed in the case of brass electrode. Copper, owing to its highest electrical conductivities, offers efficient and smooth current flow for the spark discharges and removes workpiece material effectively29. Moreover, its higher thermal conductivity facilitates quick dissipation of heat and consumes less energy in resistive heating. Efficient heat dissipation allows optimal discharge conditions where most of the energy is utilized in material removal. On the other hand, aluminum has an intermediate electrical and thermal conductivity compared to copper and brass; still, its EC is the highest (0.718 kWh). This is mainly due to the low thermal stability and the low melting point of aluminum (as compared to brass), which makes it unable to withstand the thermal stresses of EDM without deforming or melting. A significant amount of energy is consumed in melting and wearing down the aluminum electrode material instead of eroding the workpiece material. The sparking intensity of all electrode materials and the amount of workpiece material removal at time ât âare illustrated in Fig. 4.

The schematic illustration depicts the sparking intensity; amount of workpiece material removed at time t and volume of dielectric fluid consumed during the EDM process for (a) aluminum, (b) brass and (c) copper electrodes.

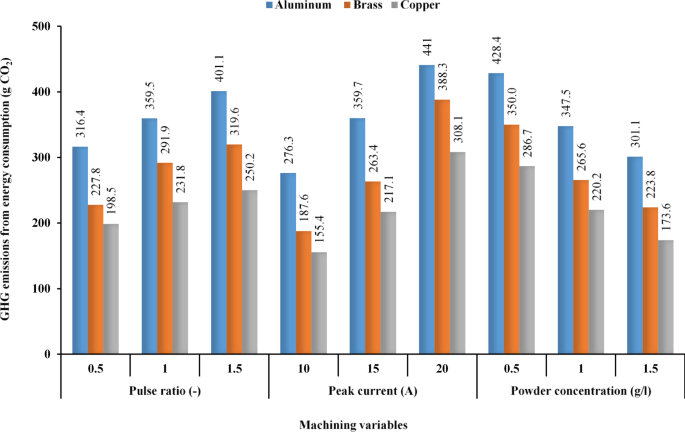

GHG emissions due to EC mainly rely on the source of electricity. In the case of China, the power sector mainly relies on thermal, solar, hydro, nuclear and wind power. Percentage contribution of different power sources and their respective carbon emissions are provided in Table 6. Based on the contributions and GHG emissions, the carbon emission factor has been computed as 0.6144 kgCO2 eq./kWh for Chinaâs electricity. The mean effects of EDM variables on GHG emissions due to the utilization of electrical energy have nearly the same trends as discussed for EC. It has been observed that GHG emissions due to EC rose from 198.5 to 250.2 g CO2 with an increase in PR from 0.5 to 1.5, as shown in Fig. 5. This increase in GHG emissions is more significant in the case of the aluminum electrode than the brass electrode. An increase in IP from 10 to 20 A also raises the GHG emissions (from EC) from 155.4 to 308.1 g CO2 for the copper electrode. Subsequent GHG emissions have been observed in the case of brass electrode, while aluminum electrode yields significantly higher GHG emissions ranging from 276.3 to 441 g CO2. GHG emissions from EC decrease from 186.7 to 173.6 g CO2 with the increase in PC from 0.5 to 1.5 g/L in the dielectric fluid while using copper electrode. Relatively higher GHG emissions have been observed for the brass electrode, followed by the aluminum electrode when PC is increased.

Mean effects analysis of EDM variables for GHG emissions from EC.

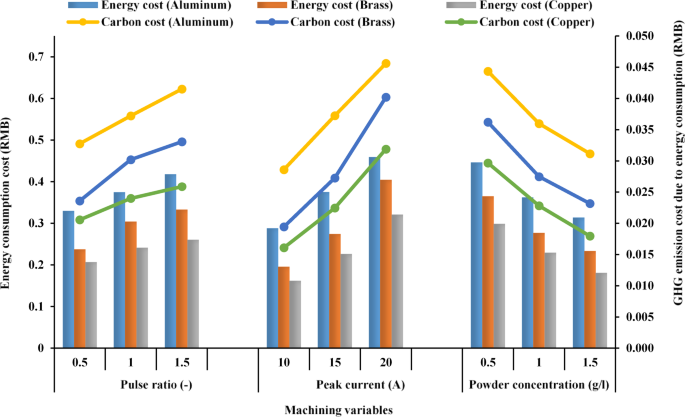

While computing the machining cost due to EC, two types of costs are considered: one is the direct cost incurred due to the consumption of electricity, and the second one is the environmental taxes incurred due to the GHG emissions produced by the EC. Although the carbon cost is not significant as compared to the direct cost, it still needs to be considered to provide accurate costing methodologies to the manufacturing industry, where a significant amount of energy is consumed. Unit electricity cost of 0.64 RMB/kWh (commercial unit price) and unit carbon cost of 103.49 RMB/tonne CO2 have been considered in this study. It has been observed that the energy cost rose from 0.207 to 0.261 RMB with an increase in PR from 0.5 to 1.5 while carbon cost increased from 0.0205 to 0.0259 RMB for copper electrode (Fig. 6). Brass electrodes offer subsequent higher energy and carbon costs, followed by aluminum electrode. With the increase in IP, the energy cost rises significantly from 0.162 to 0.321 RMB, while carbon cost also has a relative hike from 0.0161 to 0.0319 RMB in the case of copper electrode. Aluminum and brass electrodes also have a similar pattern for the associated cost increment with respect to the IP. An increase in PC from 0.5 to 1.5 g/L reduces the energy cost from 0.299 RMB to 0.181 RMB and its associated carbon cost from 0.0297 to 0.0180 RMB for copper electrode. A similar trend has been observed for aluminum and brass electrodes.

Mean effects analysis of EDM variables for EC cost and its associated carbon cost.

Analysis of electrode wear, GHG emissions, and associated costs

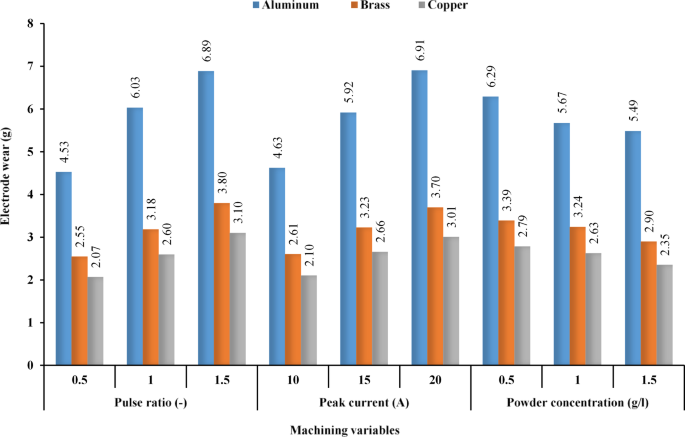

During the material removal process, spark discharges not only eradicate the workpiece material but also remove some of the electrode material from its facing surface, which is regarded as EW. The worn surface of the electrode significantly influences the workpiece surface characteristics and dimensional accuracy; therefore, it is inevitable to consider EW as one of the key performance measures in the EDM process. Like other performance measures, EW is also influenced by the selected EDM variables. It has been analyzed that the increase in PR from 0.5 to 1.5 expedited the EW (Fig. 7). A lower PR (lower PON and higher POFF) provides less time for the spark discharges to deliver the energy, resulting in less removal of the workpiece and electrode material. Moreover, a longer POFF in a lower PR provides more time for the electrode to cool, which prevents electrode facial surface from melting and evaporation and maintains its structural integrity. At a higher PR, PON is higher and supplies more discharge energy to the machining zone, resulting in the melting of material from electrode surface. A shorter POFF at a low PR remains insufficient for cooling, exacerbating thermal erosion. In addition, insufficient flushing of debris during a short POFF leads to localized wear spots on the electrode surface, as accumulated particles cause micro-cutting/erosion effects31. A rise in IP from 10 to 20 A increases thermal and mechanical wear. At higher IP, more discharge energy is supplied to the machining zone, which melts and evaporates the electrode material, resulting in increased wear and vice versa. Increased melting of electrode and workpiece material at higher IP produce more debris, which may also cause abrasive and adhesive EW.

Mean effects analysis of EDM variables for EW.

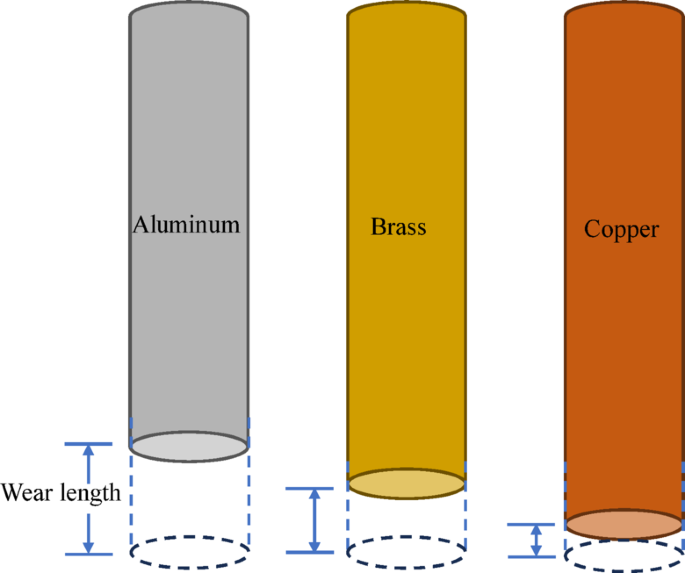

A distinct behavior for EW has been observed by the varying nano-powder. It has been analyzed that the increment of graphene nanoparticles in the dielectric fluid from 0.5 to 1.5 g/L reduces the EW to a significant extent. The increment of the graphene particles enhances the electrical conductivity of the dielectric fluid and allows the stable and efficient distribution of spark discharges. Moreover, the higher thermal conductivity of the graphene nanoparticles helps in the dissipation of heat energy effectively and prevents the temperature rise on the electrode surface, hence minimizing its thermal erosion. The comparative analysis of electrode materials depicts that copper electrodes offer the least wear during the EDM process (2.07 g), as shown in Fig. 7. This is mainly due to its higher melting point (1083 °C), which makes copper more resistant to melting and erosion. On the other hand, brass has a lower melting temperature (940 °C) than copper; therefore, more erosion results when intense spark discharge is produced in the machining zone. Aluminum has the lowest melting temperature (660 °C), which indicates that it is highly susceptible to elevated temperatures during machining. For this reason, higher EW has been perceived in the case of aluminum electrode, followed by brass and copper. Comparative wear of aluminum, brass and copper electrodes after the machining trials has been illustrated schematically in Fig. 8.

Comparative analysis of EW through schematic illustration.

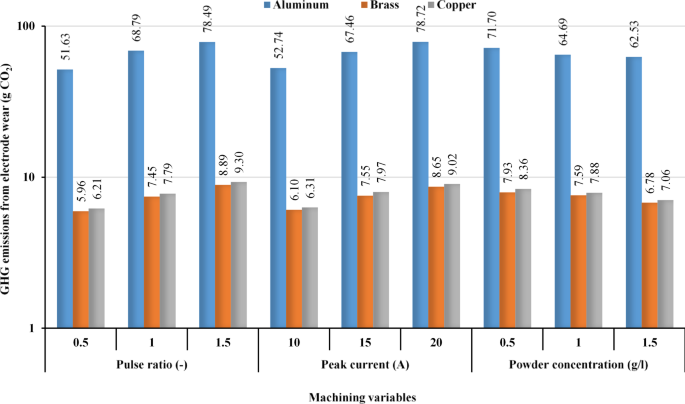

The extraction and manufacturing process of metals and alloys produce significant amounts of emissions to the environment, which canât be ignored when utilizing these materials. In the EDM process, the electrode material is melted and vaporized, which is hard to recycle. Therefore, it is necessary to estimate the GHG emissions produced due to electrode erosion/consumption. Emissions produced due to the unit production of electrode materials are provided in Table 7. Mean effects analysis has been performed for the GHG emissions released due to EW. It has been observed that the increase in PR from 0.5 to 1.5 aggravated the GHG emissions from 6.21 to 9.30 g CO2 using copper electrode (Fig. 9). However, brass electrode offered relatively less GHG emissions than copper electrode, which is mainly due to the inclusion of a significant proportion (30%-40%) of zinc metal in the brass alloy, whose extraction and processing yields reduced emissions. In the case of aluminum electrode, GHG emissions are significantly higher than those of copper and brass electrodes, ranging from 51.63 to 78.49 g CO2. Higher GHG emissions due to aluminum electrode are attributed to two prime reasons: first is the highest wear of aluminum electrode (due to its low melting point), and second is its excessive GHG emissions of 11.4 kg CO2 eq. (per kg) which are nearly 4â~â5 times higher than copper and brass. Further, the increase in IP from 10 to 20 A also exaggerated the GHG emission from 6.31 to 9.02 g CO2 for copper electrode, which is attributed to an increase in its wear rate. Comparable trends are observed for brass and aluminum electrodes; however, its quantification is significantly higher for the aluminum electrode. Increase in the graphene nanoparticles in the dielectric fluid from 0.5 to 1.5 g/L aid in reducing the GHG emissions from 8.36 g CO2 to 7.06 g CO2 for the copper electrode. Increased proportion of nanoparticles enhanced the conductivity of the dielectric medium, which reduces the EW and its associated GHG emissions. Similarly, substantially higher GHG emissions are due to aluminum electrode erosion, ranging from 71.70 to 62.53 g CO2.

Mean effects analysis of EDM variables for GHG emissions due to EW.

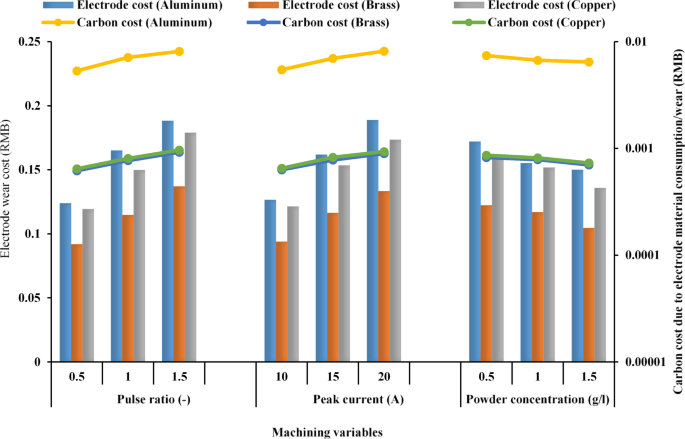

EW not only contributes to GHG emissions but also encounters the tooling cost. This tooling cost mainly includes the direct cost of the EW/consumption, and the other one is its carbon cost. Unit material cost of electrodes and dielectric fluid are provided in Table 8. As EW accelerates with the increase in PR (0.5â1.5), electrode consumption/wear cost of copper and its associated carbon cost also increases from 0.119 to 0.179 RMB and from 0.00064 to 0.00096 RMB, respectively (Fig. 10). The EW cost and carbon cost of brass are significantly lower than copper due to its reduced unit cost (36.08 RMB/kg). It has been analyzed that the unit cost of aluminum is the lowest (27.35 RMB/kg), and its EW cost is even higher than copper electrode (ranging from 0.124 to 0.188 RMB), which is primarily due to elevated EW with the increase in PR. A rise in IP from 10 to 20 A also increases the EW and its direct material and carbon costs of copper from 0.121 to 0.174 RMB and from 0.00065 to 0.00093 RMB, respectively. Aluminum also again has the highest EW cost, while brass has the least cost when varying the IP. Increased nanoparticlesâ proportion in the dielectric fluid aids in reducing EW and its material cost and associated carbon cost. The EW cost of copper is reduced from 0.161 to 0.136 RMB, and its carbon cost also decreased from 0.00087 to 0.00073 RMB when graphene nanoparticles increased from 0.5 to 1.5 g/L. Similar behavior has been observed in the case of brass and aluminum electrodes.

Mean effects analysis of EDM variables for EW cost and its associated carbon cost.

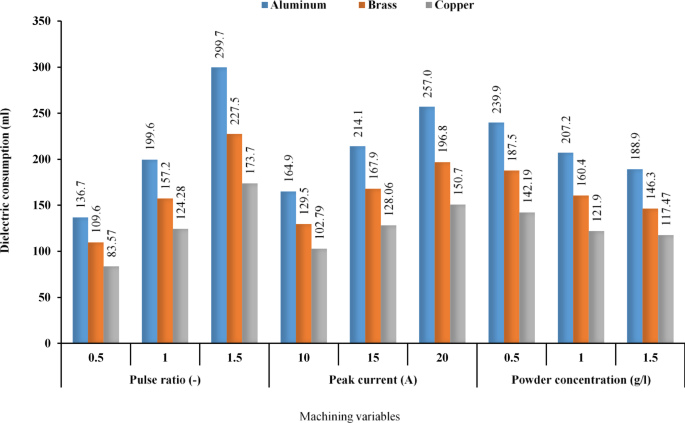

Analysis of dielectric fluid consumption, GHG emissions, and associated costs

In the EDM process, dielectric fluid is also consumed due to evaporation and decomposition, which not only produces GHG emissions but also incur costs. In this study, kerosene oil is used as a dielectric fluid with a boiling point of 300 °C, while temperature in the machining zone can rise to 12,000 °C. The temperature in the surrounding region also rises to 1000 °C, which can easily evaporate the dielectric fluid. Therefore, it is required to optimize the EDM variables to minimize dielectric fluid consumption to limit the machining cost. Mean effects analysis revealed that the increase in PR from 0.5 to 1.5 significantly raised the consumption of dielectric fluid (Fig. 11). At a lower PR (0.5), PON is almost half of the POFF, which means that the heat generated due to spark discharges will remain only for a short duration, and there will be more duration (POFF) to cool down the dielectric fluid in the machining zone. At a PR of 1.5, the PON is almost 50% higher than the POFF, and spark discharges are produced for a longer time span. Therefore, the heat will remain in the machining zone for more time and accelerate the evaporation of dielectric fluid. Moreover, low POFF will provide an insufficient duration for cooling down the dielectric fluid and building up the heat in the machining zone, and this phenomenon also contributes to the higher evaporation of dielectric fluid. In the case of a rise in IP from 10 to 20 A, the intensity of spark discharge increases significantly, generating tremendous heat in the machining zone. This elevated temperature leads to the increased evaporation rate of dielectric fluid. Mean effect analysis revealed that the increase in the proportion of graphene nanoparticles from 0.5 to 1.5 g/L positively influenced the dielectric fluid consumption. Graphene nanoparticles, owing to their higher thermal conductivity (4000 W/mK), increase the overall thermal conductivity of the dielectric fluid and allow more efficient heat dissipation. This effective heat dissipation helps lower the maximum temperature in the machining zone, potentially reducing the evaporation rate of the dielectric fluid. Moreover, the increase in the quantity of nanoparticles increases the viscosity of the dielectric fluid and limits the ability of the dielectric fluid to evaporate.

Mean effects analysis of EDM variables for dielectric fluid consumption.

In the comparison of electrode materials, it has been shown that copper has the least dielectric fluid consumption, as shown in Fig. 11. Even though copper has the highest electrical conductivity of 58.5âÃâ106 s/m, it may evaporate more dielectric fluid from the machining zone. However, it has higher thermal conductivity along with higher conductivity of the dielectric fluid (due to highly conductive graphene nanoparticles), dissipating the heat energy in the machining zone more effectively, and it may not lead to as much localized heating in the dielectric fluid. Therefore, low dielectric fluid consumption has been observed in the case of copper electrode. Brass has the lowest thermal conductivity of 150 Wm-1 K-1 among all electrodes, which means brass electrode may experience more localized heating, potentially leading to greater evaporation of the dielectric fluid in the immediate vicinity of the electrode, resulting in relatively higher dielectric fluid consumption. The analysis shows that aluminum has the highest dielectric fluid consumption among all electrodes, even though it has more reasonable electrical and thermal conductivities than the brass electrode. Dielectric fluid consumption is also associated with a higher wear rate of aluminum electrode. Rapid wear of aluminum electrode increases the spark gap between electrode and workpiece, resulting in more dielectric fluid in the machining zone and higher dielectric fluid consumption due to localized heating. The consumption of dielectric fluid before and after machining trials for aluminum, brass and copper electrodes are schematically illustrated in Fig. 4.

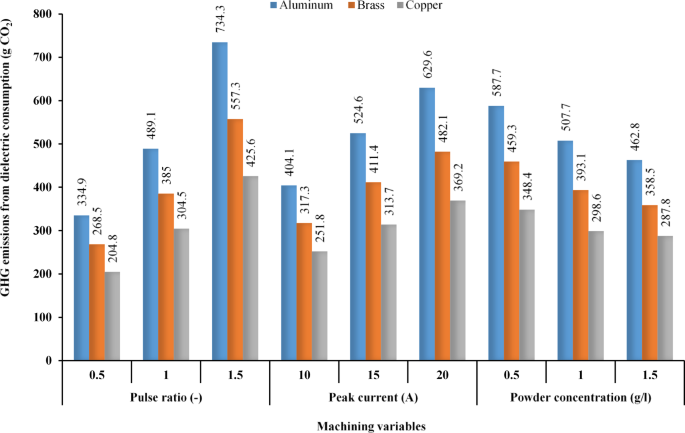

The consumption of dielectric fluid is also deemed a potential source of GHG emissions. The entire life cycle of kerosene oil, including extraction, refining and transportation, requires energy and produces GHG emissions. Higher consumption of dielectric fluid due to higher evaporation rates can exacerbate serious environmental issues. Therefore, the impact of selected EDM variables on the emissions from the dielectric fluid has been investigated. Mean effects analysis shows that GHG emissions from the DC significantly rose from 204.8 to 425.6 g CO2 using a copper electrode with the increase in PR from 0.5 to 1.5 (due to spark discharges for longer duration), as shown in Fig. 12. Comparative analysis of electrode material shows that aluminum electrode offers notably lower GHG emissions, ranging from 334.9 to 734.3 g CO2 upon increasing PR, while brass electrode has moderate GHG emissions. An increase in IP from 10 to 20 A elevates the GHG emissions from 251.8 to 369.2 g CO2 for copper electrode. A similar trend with lower value has been observed for aluminum followed by brass electrode. A rise in the graphene PC in the dielectric fluid decreases the GHG emissions from 348.4 to 287.8 g CO2 (for copper electrode) due to uniform heat distribution in the surroundings, reducing the chances of dielectric fluid evaporation. Aluminum and brass electrodes also have nearly the same pattern for the reduction in GHG emissions; however, brass offers the lowest GHG emissions.

Mean effects analysis of EDM variables on GHG emissions due to dielectric fluid consumption.

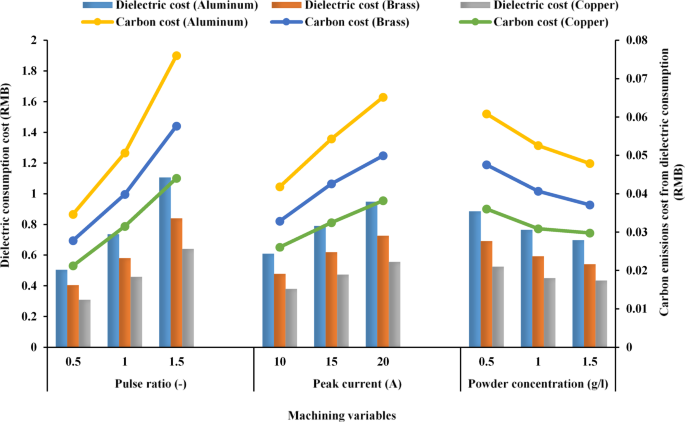

Intense sparking in the cutting zone evaporates dielectric fluid to a significant extent, incurring the cost. The PR increases the direct DC cost and its carbon cost from 0.308 to 0.641 RMB and from 0.021 to 0.044 RMB, respectively, for the copper electrode (Fig. 13). At the same time, aluminum electrode incurs a higher cost, followed by brass electrode, which has a slightly lower cost (than aluminum), with similar trends. In the case of a rise in IP (using copper electrode), dielectric fluid consumption cost and its carbon cost increased from 0.379 to 0.556 RMB and 0.026 to 0.038 RMB, respectively. The application of aluminum electrode has the highest DC and carbon cost, whilst brass electrode encounters relatively lower costs. Increasing the graphene nanoparticles in the dielectric fluid reduces the DC cost due to the limited evaporation of kerosene oil. It has been observed that the increment in nanoparticle proportion resulted in decreasing direct dielectric fluid cost and its carbon cost from 0.525 to 0.434 RMB and from 0.036 to 0.030 RMB, respectively, for copper electrode. Similar trends have been observed for other electrodes; however, dielectric fluid cost and its carbon cost are relatively higher for aluminum electrode; however, brass electrode offers moderate costs.

Mean effects analysis of EDM variables for dielectric fluid consumption cost and its associated carbon cost.

Significant effect analysis

Among different EDM variables, IP has been observed as most significant due to its major contribution of 52.73%, 59.33% and 57.76% to the EC for aluminum, brass and copper electrodes, respectively. However, the PC has the second largest contribution to EC, while the PR has the least contribution. Based on the experimental results, empirical relationships are developed between EDM variables and response measures. Using correlations and pattern identified, regression models are developed to predict scenarios other than the experimental ones. It has been observed that the regression models developed have p-values less than 0.05, which shows the significance of the models. Moreover, the adequacy of models has also been assessed based on the coefficient of determination R2, R2 (adjusted) and R2 (predicted), which depicts the accuracy of the prediction capabilities of the developed models. From Table 9, it can be analyzed that the adequacy measures include numeric values close to unity, which depicts the effectiveness and reliability of the developed models. The regression models for EC for aluminum, brass and copper electrodes have been provided as Eqs. (11)â(13), respectively.

Analysis of EW shows that the EDM variables such as PR, IP, and PC have p-values of less than 0.05, which is significant; however, their percentage contribution to the EW varies. From Table 9, it can be seen that PR has the highest contribution of 43%, 48.28% and 47.46% for aluminum, brass and copper electrode, which shows that a slight variation in PR can significantly affect the EW. However, IP makes the second most significant contribution to EW for all electrode materials, followed by PC. The P-value of regression models for EW revealed that the developed models are significant. It supports the significance of the independent variables in explaining the variability in the dependent variable. Moreover, the adequacy measures (R2, R2 (adjusted) and R2 (predicted)) are close to 1, which depicts a well-fitting regression model with meaningful relationships between variables. The developed models for EW for all electrode materials have been provided in Eqs. (14)â(16).

ANOVA has also been performed for dielectric fluid consumption for aluminum, brass and copper electrodes (Table 9). It has been observed that the p-values for all EDM variables are less than 0.05, which depicts their significance as illustrated in Table 9. However, percentage contribution has been assessed to differentiate among the variables, which shows that the PR has the most significant contribution of 69.45%, 68.12% and 72.84% for aluminum, brass and copper electrodes. On the other hand, IP has the subsequent most contribution to dielectric fluid consumption while PC has the least contribution of 6.79%, 8.31% and 5.48% to the dielectric fluid consumption for aluminum, brass and copper electrodes, respectively. The p-values for the regression models are also less than 0.05, which depicts the significance of the independent variables in explaining the variability in the dependent variable. The analysis of the adequacy measures revealed that the values of the coefficient of determination are close to unity, which shows that the models are efficient enough to predict the dielectric fluid consumption values with great accuracy. The developed regression models for the prediction of dielectric fluid consumption are provided in Eqs. (17)â(19) for all electrode materials.

$$\text{EC }(\text{Aluminum})=0.2520+0.1377\times {\text{P}}_{\text{R}}+0.02680\times {\text{I}}_{\text{P}}-0.2073\times {\text{P}}_{\text{C}}$$

(11)

$$\text{EC }(\text{Brass})=0.0214+0.1494\times {\text{P}}_{\text{R}}+0.03267\times {\text{I}}_{\text{P}}-0.2054\times {\text{P}}_{\text{C}}$$

(12)

$$\text{EC }(\text{Copper})=0.0964+0.0841\times \text{P}_{\text{R}}+0.02485\times \text{Ip}-0.1841\times \text{Pc}$$

(13)

$$\text{EW }(\text{Aluminum})=0.84+2.356\times {\text{P}}_{\text{R}}+0.2279\times {\text{I}}_{\text{P}}-0.804\times {\text{P}}_{\text{C}}$$

(14)

$$\text{EW }(\text{Brass})=0.778+1.251\times {\text{P}}_{\text{R}}+0.1093\times {\text{I}}_{\text{P}}-0.492\times {\text{P}}_{\text{C}}$$

(15)

$$\text{EW }\left(\text{Copper}\right)=0.636+1.031\times {\text{P}}_{\text{R}}+0.0902\times {\text{I}}_{\text{P}}-0.431\times {\text{P}}_{\text{C}}$$

(16)

$$\text{DC }(\text{Aluminum})=-38.1+163.0\times {\text{P}}_{\text{R}}+9.20\times {\text{I}}_{\text{P}}-51.0\times {\text{P}}_{\text{C}}$$

(17)

$$\text{DC }(\text{Brass})=-12.9+117.86\times {\text{P}}_{\text{R}}+6.728\times {\text{I}}_{\text{P}}-41.16\times {\text{P}}_{\text{C}}$$

(18)

$$\text{DC }(\text{Copper})=-10.1+90.13\times {\text{P}}_{\text{R}}+4.791\times {\text{I}}_{\text{P}}-24.71\times \text{Pc}$$

(19)

Overall GHG emissions and carbon cost assessment

Comprehensive analysis shows that energy, electrode material and dielectric fluid are the three major contributors to the GHG emissions produced during the EDM process. However, electrode materials have distinct behavior for GHG emission sources. From Table 10, it can be observed that aluminum has higher GHG emissions from EC, EW and dielectric fluid consumption. In contrast, brass has moderate GHG emissions from EC and dielectric fluid and offers the lowest GHG emissions in terms of EW. Copper electrode yields the lowest GHG emissions due to EC and dielectric fluid consumption, and its EW yields moderate GHG emissions. The overall selection of the best electrode materials for a sustainable and environmentally friendly EDM process depends on the quantification of GHG emissions from all sources.

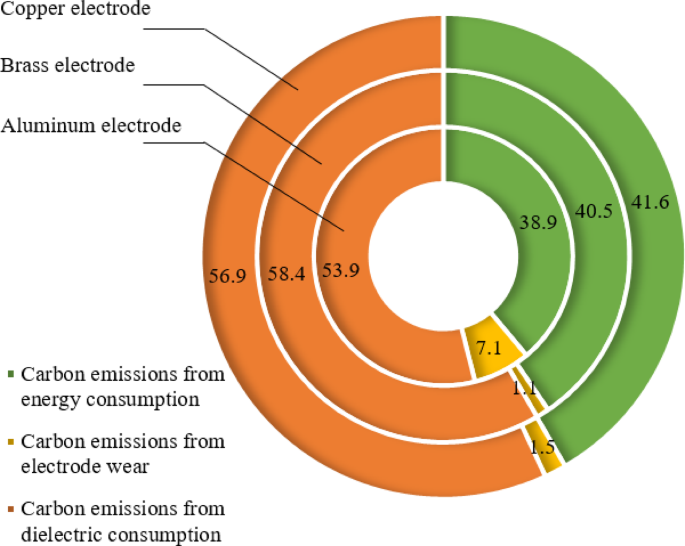

The quantification of GHG emissions is distinct for each source; for example, GHG emissions for dielectric fluid consumption are significantly higher than those of other sources (EC and EW). The percentage of GHG emissions from different sources for all electrode materials have been provided in Fig. 14. In the case of copper electrode, dielectric fluid consumption contributes almost 56.9%, while EC has a subsequent contribution of 41.6% to the overall GHG emissions. EW, on the other hand, has the lowest contribution of 1.5% to the overall GHG emissions as a very small amount of electrode material is consumed/eroded during the EDM process, specifically in the case of copper electrode (due to its higher melting point). The brass electrode has nearly similar behavior in terms of the contribution of different carbon sources. In the case of aluminum electrode, the percentage contribution of GHG emissions from EW is significantly higher (7.1%) than others. These emissions are mainly attributed to the higher EW rate of aluminum and significantly higher GHG emissions per kilogram of aluminum (due to its extraction and processing) than copper and brass materials.

Percentage contribution analysis for the GHG emission factors (EC, EW and dielectric fluid consumption).

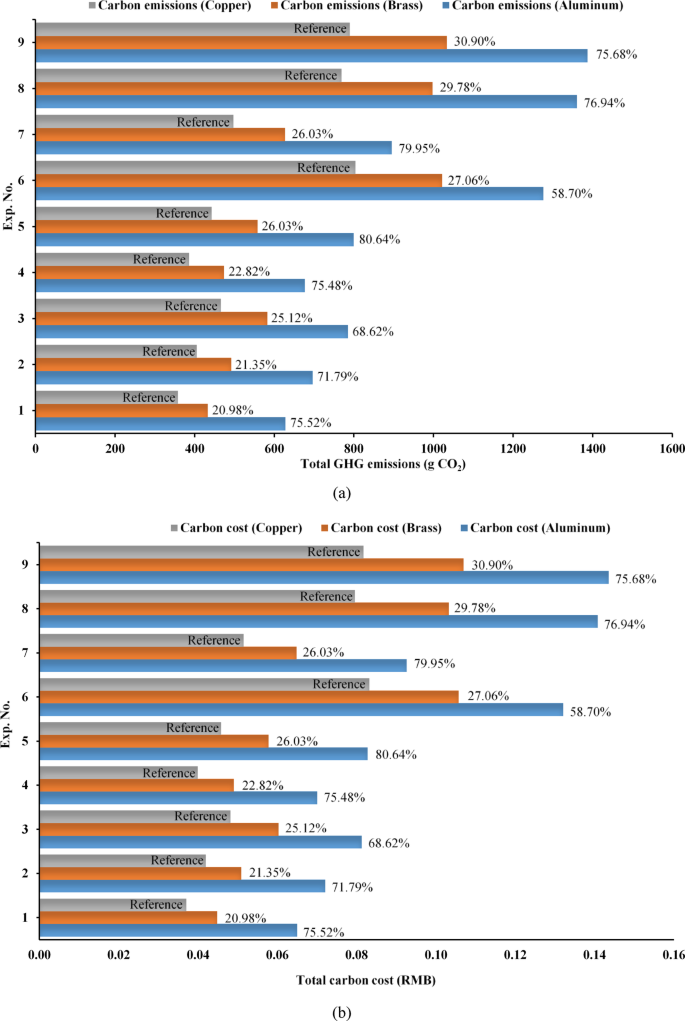

Owing to the distinct behavior of electrodes, it is necessary to assess their cumulative effects for the selection of environmentally friendly alternatives for electrodes in the EDM process. The analysis shows that aluminum electrode has the highest GHG emissions and carbon cost than copper and brass, as shown in Fig. 15. A comprehensive analysis has been conducted with reference to the copper electrode due to its better performance in terms of GHG emissions and carbon cost. It can be analyzed that the brass electrode yields higher GHG emissions and carbon cost ranging from 20.98 to 30.90% than the copper electrode. However, the usage of aluminum electrode yield significantly higher GHG emissions and carbon costs are 58.70â~â80.64% than copper. Comparative analysis shows that pure copper can be used as electrode material in order to limit GHG emissions and carbon cost from EC, EW and dielectric fluid consumption.

Percentage comparative analysis for electrode materials for (a) total GHG emissions and (b) total carbon cost.

Sustainable development goals

This study evaluates key environmental and economic parameters of EDM applied to SS316L, focusing on EC, EW, dielectric fluid usage, greenhouse gas emissions, and their associated costs. These parameters have direct implications on several SGDs, indicating the broader relevance of this work beyond manufacturing efficiency.

SDG 7: Affordable and Clean Energy

EC in EDM significantly impacts SDG 7 (Affordable and Clean Energy). High energy use not only increases operational costs but also strains energy resources and contributes indirectly to carbon emissions34. By analyzing and optimizing energy input, this research supports more efficient industrial energy use, promoting cleaner production methods that align with the global goal of energy sustainability.

SDG 9: industry, innovation, and infrastructure

The wear of electrodes directly relates to SDG 9 (Industry, Innovation, and Infrastructure)35 and SDG 12 (Responsible Consumption and Production)36,37. Electrode consumption reflects material usage efficiency; excessive wear leads to increased demand for raw materials and waste generation. Improving electrode longevity and minimizing wear helps reduce resource depletion and supports sustainable industrial practices by promoting material conservation and reducing manufacturing waste.

SDG 12: responsible consumption and production

Dielectric fluid usage further ties into SDG 1238. Dielectrics in EDM often contain chemicals that can pose environmental risks if not managed responsibly. Optimizing DC reduces chemical waste and potential environmental contamination, aligning the manufacturing process with responsible resource management and waste minimization goals.

SDG 13: climate action

Importantly, the measurement of GHG emissions connects this research to SDG 13 (Climate Action)39. EDM processes consume electricity which, depending on the energy source, contributes to carbon emissions. Quantifying and seeking to reduce these emissions through process optimization contributes to mitigating climate change impacts, reinforcing the necessity of integrating climate considerations in manufacturing innovations.

Finally, assessing the cost implications of these environmental parameters reinforces the economic dimension of sustainability embedded in SDGs 7, 9, and 12. Efficient energy use, reduced material consumption, and minimized environmental impact translate into lower operating costs and improved economic viability, encouraging wider adoption of sustainable manufacturing technologies. In summary, this investigation demonstrates that improving EDM process parameters not only enhances machining efficiency but also contributes meaningfully to the global agenda for sustainable industrial development as shown in Fig. 16. Such integration of environmental and economic considerations is essential to transition manufacturing sectors toward sustainability and fulfill the commitments outlined in the SDGs.

SGDs for current study targeting low EC, less material consumption, favoring sustainable usage of dielectric, and reducing less CO2 emissions.